Better than 0.1 microns, at real-time measurement rates of up to 500 hertz

Rugged design for use in real industrial environments

Pre-calibrated optics and ready out of the box

Tolerant of low and variable lighting conditions

Mobius offers a highly effective alternative to traditional displacement sensors such as LVDTs, DTs, EDMs, encoders, laser trackers, and potentiometers across various applications. By utilising non-contact digital image correlation techniques, it eliminates the challenges of traditional contacting sensors.

The Measurement Head comes with a factory-calibrated measurement volume, removing the need for user calibration. User 3D validation wizard tools enable users to determine system measurement accuracy when needed.

Mobius uses Imetrum’s Video Gauge™ software, which includes a range of mathematical functions for analysing the behaviour of the component under test.

The Unified Coordinate System allows you to connect up to three Mobius Measurement Heads and measure within a single coordinate system. This integration ties together multiple views of the same test object without requiring each Measurement Head to share an overlapping field of view.

You connect each Mobius Measurement Head to the same high-performance, rack-mounted System Controller.

Rigid Body Motion correction enables accurate measurements to be made relative to a moving object. Mobius measures relative to a set of reference points defined on a rigid body. If the rigid body reference points move during the test, it automatically compensates, resulting in the true motion of an object being measured.

For example, Mobius measures an aircraft winglet relative to the fuselage. Without Rigid Body Motion correction, all displacement of the winglet would be attributed to the winglet itself, even if the movement is primarily due to the pitch, roll, or yaw of the entire aircraft.

Mobius is highly suitable for wind tunnel applications including both aerospace and motorsport. With several systems used in Formula 1.

It’s non-contact nature allows for measurements remote to the working section and object under test. This ability, combined with that to replace multiple contacting sensors simultaneously, delivers accurate data not otherwise possible. Mobius can replace traditional displacement sensors such as LVDTs, DTIs, EDMs, encoders, laser trackers and potentiometers.

All Mobius systems are bespoke and tailored to the customer’s needs. Whether this is the measurement volume for each Mobius Measurement Head, the wavelength of light used or installation.

All Mobius measurement heads are calibrated before delivery. This means they are ready to begin taking measurements straight out of the box, increasing productivity and simplifying the user experience. All that is needed is to align the coordinate system to define the x, y and z directions. They also do not need recalibration during their operational life, reducing downtime.

For a technical demo and more information on how Mobius can meet your measurement needs, please fill out the form below.

If you are interested in obtaining a quote or looking for additional information, please fill out the form.

"*" indicates required fields

UVX3D offers higher frame rates and advanced strain rate control capabilities

Consistent performance across a wide range of testing environments

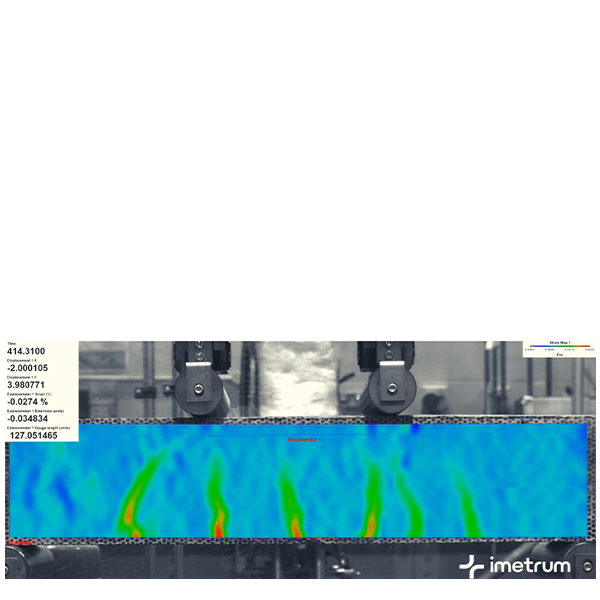

Digital Image Correlation strain and displacement maps are also available

Gauge length: 20 to 200 mm

Minimum specimen width: Axial; 7.5 mm Transverse; 25 mm

Working distance: 300 to 380 mm

Video Gauge™ forms the core of our systems

In Post Processing mode, video data can be reanalysed on any computer

Wide variety of tools and features

Imetrum Limited, The Courtyard, Wraxall Hill, Wraxall, Bristol, BS48 1NA, United Kingdom

Built by

in Bristol

We need your consent before you can continue on our website. If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. You can revoke or adjust your selection at any time under Settings.

If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.