Real-time sampling from 0.1Hz to 1000Hz

Minimal set up with real time data and full post processing capability

Measure from a position of safety with true non-contact capability

Portability for seamless transitions between test frames and environments

The Flexi Extensometer is fully customisable, allowing you to choose from a wide array of camera and lens options. Enabling you to use different lenses with a single camera, ensuring you achieve precise measurements for various gauge lengths and strain ranges.

Designed with convenience in mind, the Flexi system features a tripod mount. This allows for quick relocation between test frames or environments, enhancing your testing flexibility.

Combining these cameras with lenses from our extensive range enables you to take precision measurements at the ideal scale for your application.

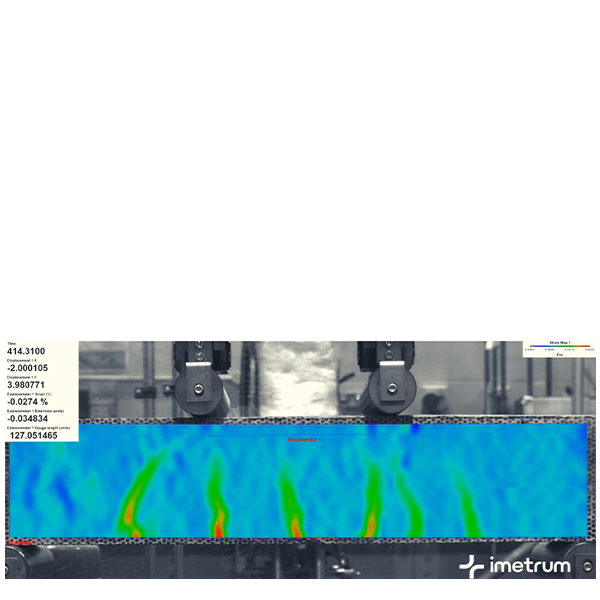

The Flexi systems use our core software platform, Video Gauge™. This provides a Digital Image Correlation tool for creating rich colour contour maps over the test object. These maps, which can show strain or displacement, offer a detailed understanding of the entire surface.

The lens selection tables and module specification sheets here enables you to select the appropriate hardware for your specific tests.

If you do not see a configuration to meet your requirements, please contact your usual Imetrum representative to assist you with selecting a combination from our extended range.

The Flexi system provides you with the data you need, whether your application is in a controlled laboratory environment or an outdoor structure with complex access needs.

Extensometer modules are available that operate from 0.1Hz to 1000Hz in real time. Speeds faster than this are available by post-processing videos recorded by ultra-high speed cameras (up to 1,000,000 Hz).

For a technical demo and more information on how Vector can meet your measurement needs, please fill out the form below.

If you are interested in obtaining a quote or looking for additional information, please fill out the form.

"*" indicates required fields

UVX3D offers higher frame rates and advanced strain rate control capabilities

Consistent performance across a wide range of testing environments

Digital Image Correlation strain and displacement maps are also available

Gauge length: 20 to 200 mm

Minimum specimen width: Axial; 7.5 mm Transverse; 25 mm

Working distance: 300 to 380 mm

Video Gauge™ forms the core of our systems

In Post Processing mode, video data can be reanalysed on any computer

Wide variety of tools and features

Imetrum Limited, The Courtyard, Wraxall Hill, Wraxall, Bristol, BS48 1NA, United Kingdom

Built by

in Bristol

We need your consent before you can continue on our website. If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. You can revoke or adjust your selection at any time under Settings.

If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.