Material Testing

Vector - The future of extensometry

An extensometer is a device that is used to measure the change in length of a material specimen. Our range of extensometers can be used throughout a variety of test scenarios in the materials testing industry.

Meeting Standards

ISO 9513 Class 0.5, part of the ISO 9513 standard, specifies the accuracy and resolution requirements for extensometer systems used in mechanical testing, ensuring precise measurements of material deformation. Extensometers under this classification have a maximum relative bias error of strain indicated of 0.5%.

ASTM E83 Class B-1, part of the ASTM E83 standard, categorises extensometer systems based on their accuracy levels, with Class B-1 representing high precision. Extensometers under this classification have a maximum error of strain indicated of 0.5%.

Through our range of extensometers, Imetrum works towards meeting and exceeding these standards in the materials testing industry to ensure reliable and accurate results.

Why use extensometers in materials testing?

Extensometry provides precise information about the straining, extension, compression and deflection of test materials under load. When high-quality measurement data is required, extensometers are an effective way to measure specimens to the required accuracy and resolution.

Extensometers

Uniaxial

What is a uniaxial extensometer?

“Uniaxial” means measuring in one direction, typically in line with the load.

Offering multiple gauge lengths from a single instrument, a Uniaxial Vector can replace numerous contacting sensors. With all Uniaxial Vector variants being capable of measuring the most common gauge lengths, the right option can be found to best fit your requirements.

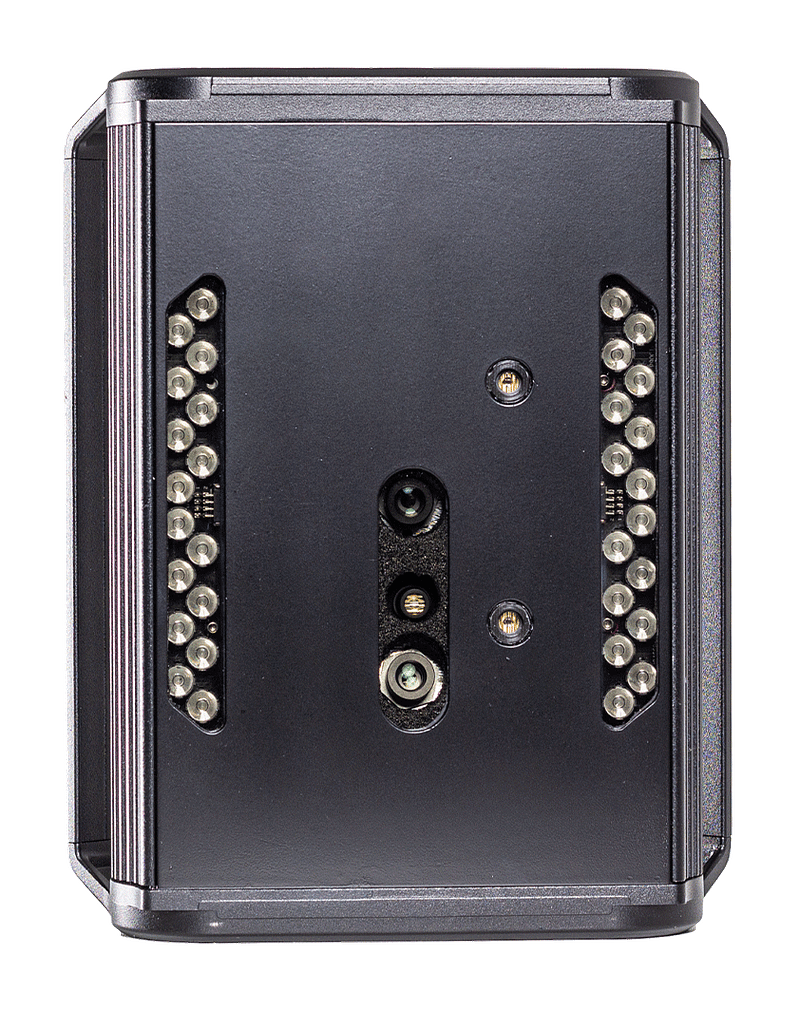

Vector U200

Vector

Uniaxial Extensometer

Gauge length: 25 to 180 mm

Minimum specimen width: 5 mm

Operating distance: 250 to 350 mm

Vector U70

Vector

Uniaxial Extensometer

Gauge length: 10 to 50 mm

Minimum specimen width: 2 mm

Operating distance: 280 to 320 mm

Extensometers

Biaxial

What is a biaxial extensometer?

Biaxial extensometers are used in materials testing to measure both axial and transverse strain. The data provided aids in the determination of material properties such as stiffness and Poisson’s ratio, particularly in advanced materials such as composites.

With enhanced resolution, B80 can also perform uniaxial testing of smaller specimens than U200 or U70. B80 is capable of meeting ISO 9513 class 0.5 and ASTM E83 class B-1 for gauge lengths greater than 7.5mm, and of specimens of width greater than 1.5mm.

In materials testing, Poisson’s Ratio describes the straining behaviour of the material in perpendicular directions below the elastic limit.

In metal testing, r-value and n-value are parameters that describe the straining behaviour of the metal in perpendicular directions through plastic deformation.

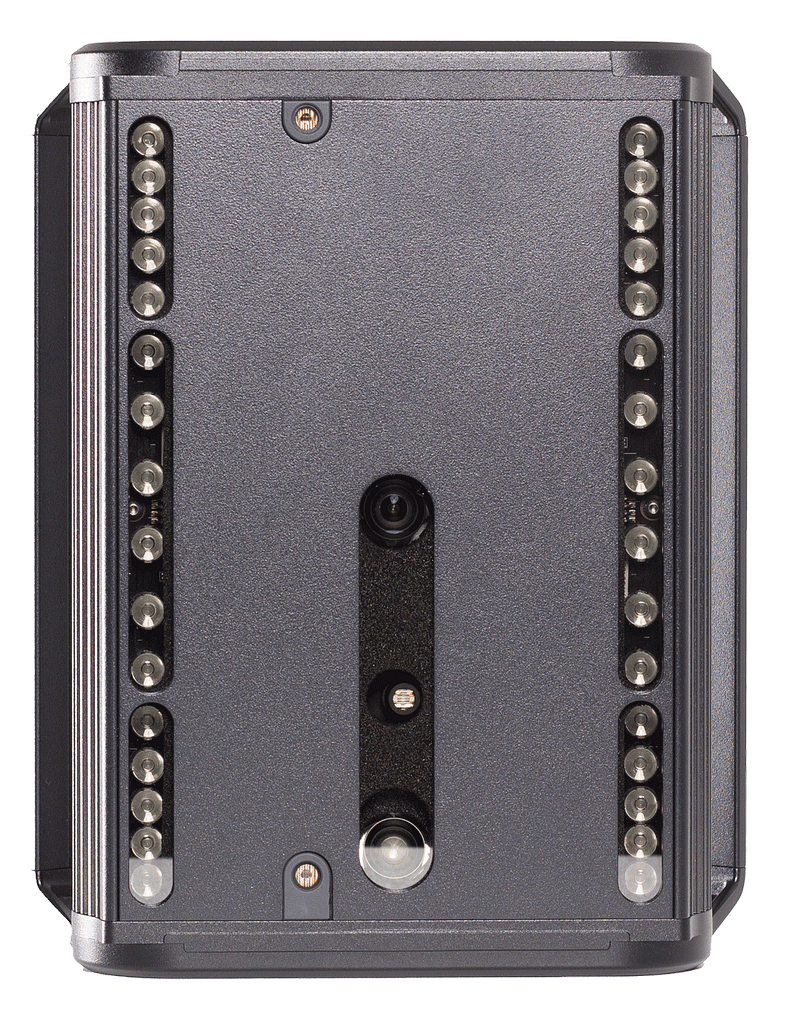

Vector B80

Vector

Biaxial Extensometer

Gauge length: Axial 7.5 to 70 mm Transverse 6 to 25 mm

Minimal specimen width: Axial 1.5 mm flat 2 mm round Transverse 10 mm flat 12.5 mm round

Operating distance: 285 to 315 mm

Extensometers

Advanced Material Testing

The research and development of modern materials requires detailed understanding of a specimen’s behaviour under load.

Advanced non-contact extensometers are ideal for the measurement of shear strain, rotation, buckling and strain over multiple points, for static and dynamic testing applications.

Video extensometry produces a detailed video archive of specimen tests which are instrumental in enriching further understanding of material properties without touching the specimen. DIC post-processing reveals strain-maps and displacement-maps, crack-length and failure-mode analysis.

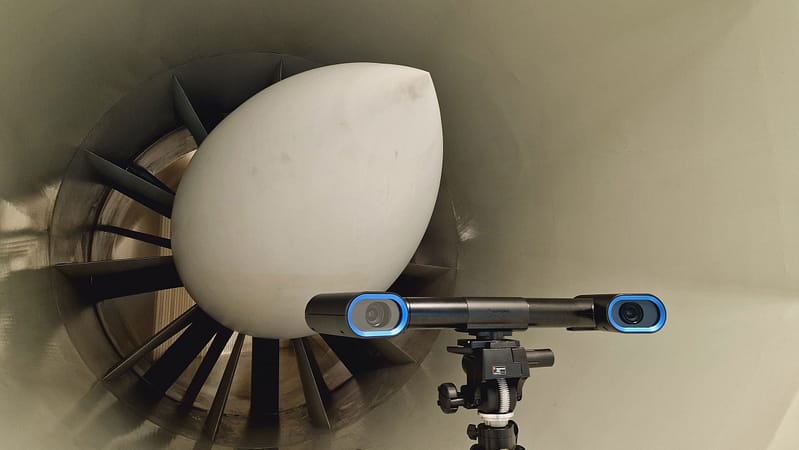

UVX3D 110

Dynamic Advanced Extensometer, Video Gauge

Gauge length: 10 to 80 mm

Minimum specimen width: Axial; 2.1 mm, Transverse; 12 mm

Working distance: 320 to 360 mm

UVX3D 220

Dynamic Advanced Extensometer, Video Gauge

Gauge length: 20 to 200 mm

Minimum specimen width: Axial; 7.5 mm Transverse; 25 mm

Working distance: 300 to 380 mm

Types of materials Testing

Clip-on Extensometer vs Advanced Extensometer vs Vector

What is the main difference between these key methods of materials testing?

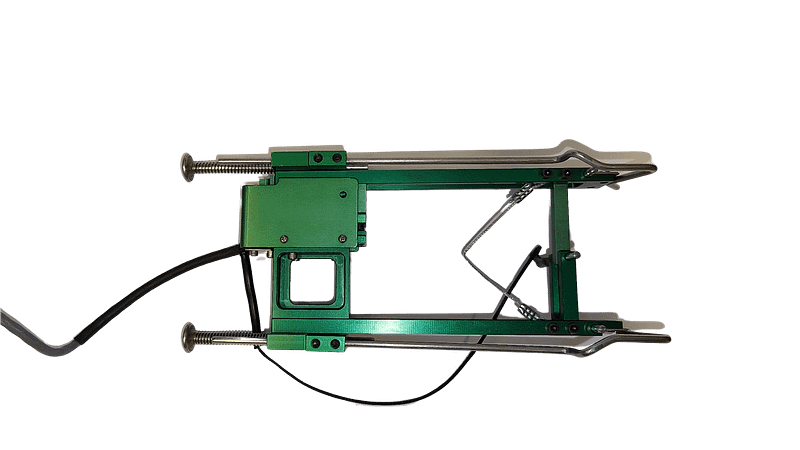

Clip-On Extensometer

Traditional extensometry has been superseded, accelerated and advanced at a very comparable price using Vector. Reliable, high-quality, real-time results are easy to achieve over a broad range of tests using Vector’s simple and intelligent approach.

Advanced Extensometer

When stringent and exploratory testing calls for advanced capability, the UVX3D provides a trusted, pre-calibrated, precision optical system with a suite of measurements and analytics.

Vector Extensometer

Pre-calibrated, non-contact, “plug and play” extensometry. Vector delivers uniaxial strain measurement over a wide range of materials, gauge lengths and set-ups that all meet or exceed ISO 9513 Class 0.5 and ASTM E83 Class B-1. Vector’s lightweight operation and convenient integration makes Vector an advancement to any material testing laboratory.