Better than 0.1 microns, at real-time measurement rates of up to 500 hertz.

Robust design for use in real industrial applications

Pre-calibrated and ready to use out of the box

Tolerant of low and variable lighting conditions

Working alongside our valued customers and partners, we have been able to develop software functionalities to enhance your testing experience. Enhance your workflow through advanced techniques such as:

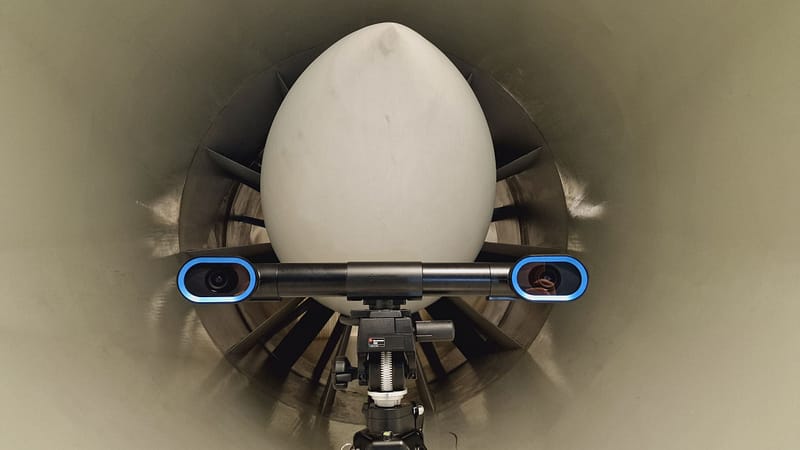

Wind tunnel testing requires capturing multiple data points simultaneously to measure displacements, strains and rotations with high precision. Traditional contacting sensors often introduce challenges such as wiring complexity, sensor interference and limited measurement range. MobiusWT overcomes these issues by providing a non-contact, high-accuracy measurement solution tailored for wind tunnel applications.

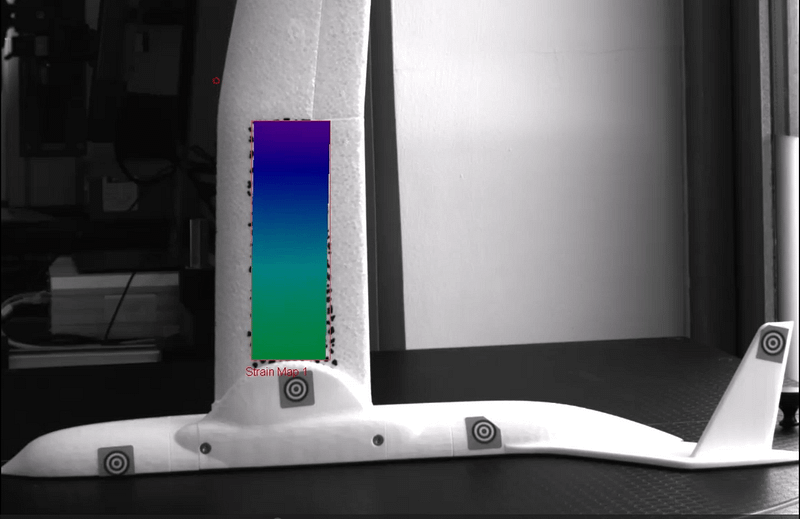

Imetrum’s Digital Image Correlation software, Video Gauge™, uses point tracking algorithms, incorporating a range of mathematical functions for analysing the behaviour of the component under test.

MobiusWT’s enhanced features are the culmination of many years of development in Imetrum’s three-dimensional displacement measurement capability. This, in combination with class leading accuracy and resolution, means it offers the most data rich output of any comparable 3D Digital Image Correlation system.

Mobius is already in use within Formula 1 and aerospace wind tunnels, demonstrating its capability to deliver data accuracy beyond traditional sensors. Its ability to work in challenging environments while maintaining sub-micron precision makes it the ideal solution for aerodynamic research.

By simplifying setup, improving accuracy and enabling deeper post-test analysis, MobiusWT transforms wind tunnel testing, ensuring researchers capture the most complete and reliable data possible.

The MobiusWT system supports full integration of its testing capability into any Wind Tunnel Control System (WTCS). A WTCS can easily be configured for remote control of MobiusWT testing via universally available TCP communication. This integration delivers a suite of simple commands which allow for automation and streamlining of the test process.

For example, test control from the WTCS enables timed synchronisation of data acquisition inline with other equipment controlled by the WTCS. During testing, live measurement data can be streamed over network protocols and automatically integrated, displayed and stored alongside other data sources. This seamless connectivity delivers simple and efficient wind tunnel testing, empowering users to get the most out of every run.

Finite Element (FE) model validation

Wing performance testing

Mobius’ suitability for wind tunnel testing lies in its ability to facilitate precise aerodynamic assessments, enabling continuous refinement of simulations and performance characteristics through controlled, repeatable research.

Imetrum provides fully tailored MobiusWT solutions, customising factors such as measurement volume, light wavelength and installation process. This ensures that each system meets the precise requirements of the application.

If you are interested in obtaining a quote or looking for additional information, please fill out the form.

"*" indicates required fields

Designed for Kinematics & Compliance testing

Integration with new and existing test rigs

Scalable for full vehicle testing

Wind tunnel model deformation measurement

Pre-calibrated optics for straight forward use

Rugged design for use in real industrial environments

UVX3D offers higher frame rates and advanced strain rate control capabilities

Consistent performance across a wide range of testing environments

Digital Image Correlation strain and displacement maps are also available

Imetrum Limited, The Courtyard, Wraxall Hill, Wraxall, Bristol, BS48 1NA, United Kingdom

Built by

in Bristol

We need your consent before you can continue on our website. If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. You can revoke or adjust your selection at any time under Settings.

If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.