Meets or exceeds ISO 9513 Class 0.5 and ASTM E83 Class B-1

Real-time data and full post processing capability

Test specimens of different geometries and dimensions without altering set up

Replaces a range of traditional sensors

Engineered to meet the highest standards of precision, the UVX3D 220 complies with ISO 9513 Class 0.5 and ASTM E83 Class B-1 standards. As a result, your testing procedures are not only compliant with global benchmarks but also delivers the reliability and accuracy you require.

For more information on compliance standards: ISO 9513 information

With a high-resolution optical system that spans a 240mm Field of View (FoV), the UVX3D 220 is ideally suited for testing materials with larger gauge lengths or those that exhibit significant plasticity or elasticity, even in materials that exhibit out-of-plane deformations. In contrast, this extensive FoV differentiates it from the UVX3D 110 model, which offers a 110mm FoV, providing a solution tailored to your specific testing requirements.

The UVX3D 220’s advanced optical setup is designed to withstand challenging environments. In particular, its enhanced immunity to glare and variations in ambient lighting ensures consistent and accurate performance, even in the most demanding conditions. Moreover, the inbuilt lighting system effectively negates environmental effects, mitigates emitted radiation from high-temperature specimens and ensures accurate measurements even in the presence of out-of-plane deformations, safeguarding the integrity of your data.

The UVX3D 220 comes with a robust frame mounting kit, designed to integrate effortlessly with the Vector Extensometer mounting system. As a result, this compatibility ensures that the extensometer can be securely and easily attached to any test frame, providing stability throughout your testing procedures. Furthermore, the ease of installation combined with the stability of the system contributes to a smoother, more efficient user experience.

If you are interested in obtaining a quote or looking for additional information, please fill out the form.

"*" indicates required fields

Designed for Kinematics & Compliance testing

Integration with new and existing test rigs

Scalable for full vehicle testing

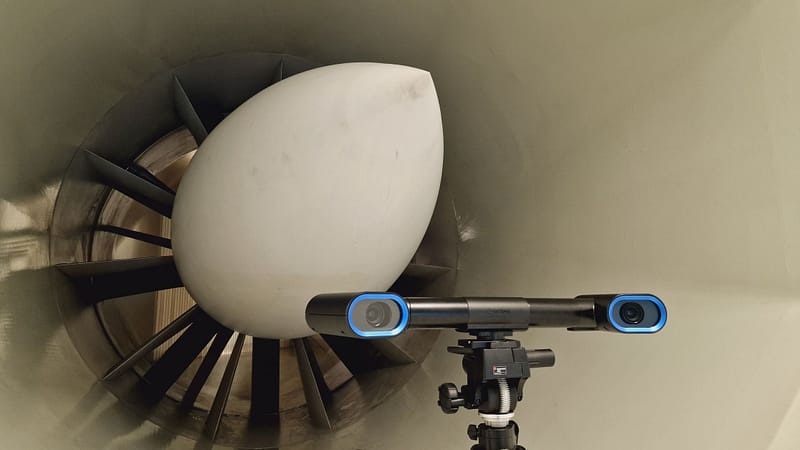

Designed for wind tunnel testing

Integration with wind tunnel control system

Fully tailored solution for individual needs.

UVX3D offers higher frame rates and advanced strain rate control capabilities

Consistent performance across a wide range of testing environments

Digital Image Correlation strain and displacement maps are also available

Imetrum Limited, The Courtyard, Wraxall Hill, Wraxall, Bristol, BS48 1NA, United Kingdom

Built by

in Bristol

We need your consent before you can continue on our website. If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. You can revoke or adjust your selection at any time under Settings.

If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.