Non-contact extensometers

Introducting Vector

Vector is the new generation of extensometers.

Building on years of measurement experience and knowledge in the material testing and metrology fields, the plug-and-play range revolutionises the industry with a non-contact, real-time approach.

Vector seamlessly integrates into your testing process, providing accurate measurements without influencing delicate specimens.

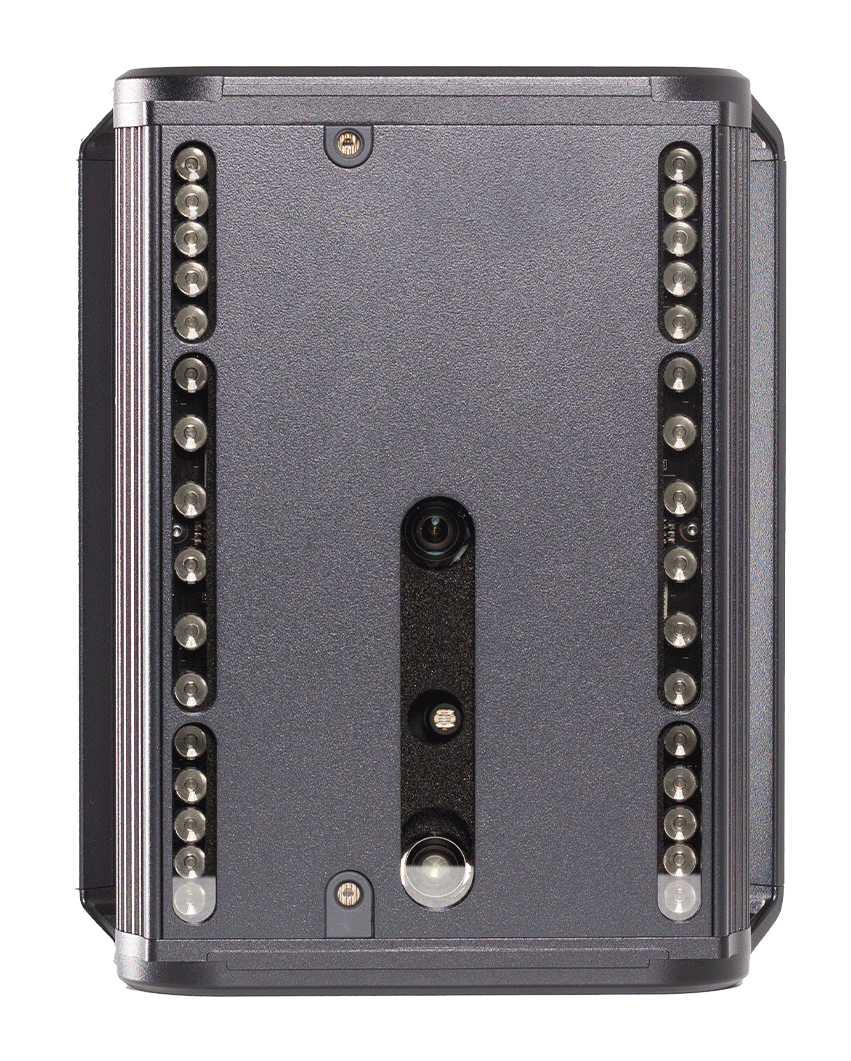

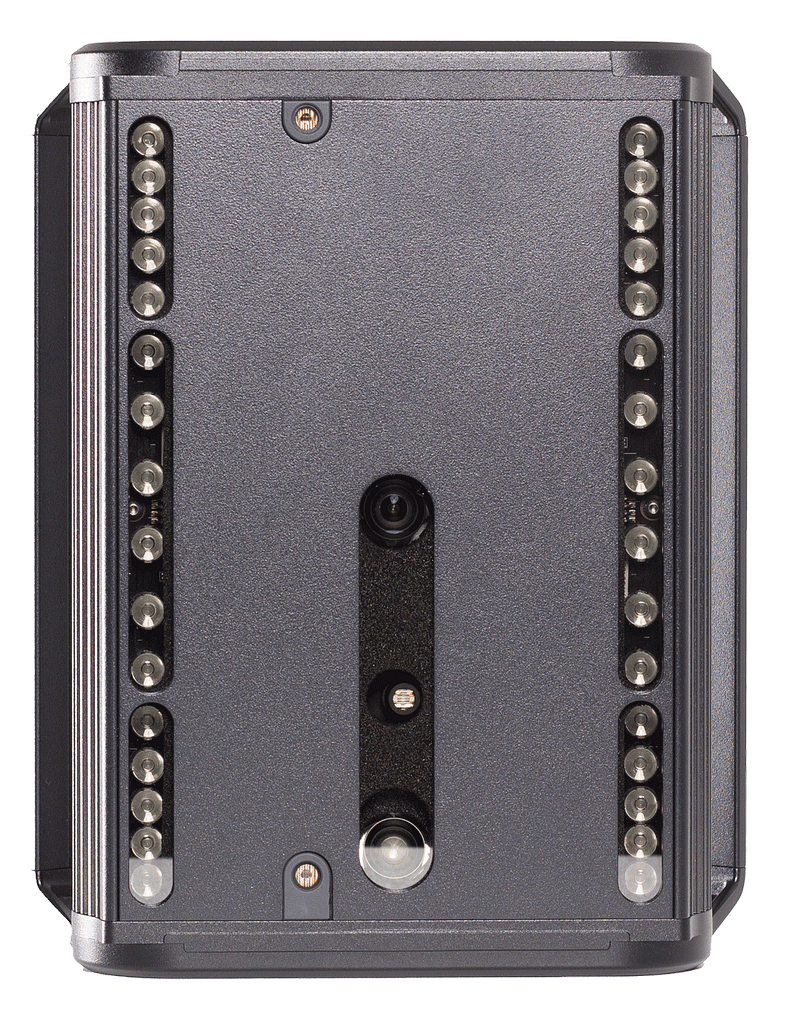

U200, Uniaxial extensometer

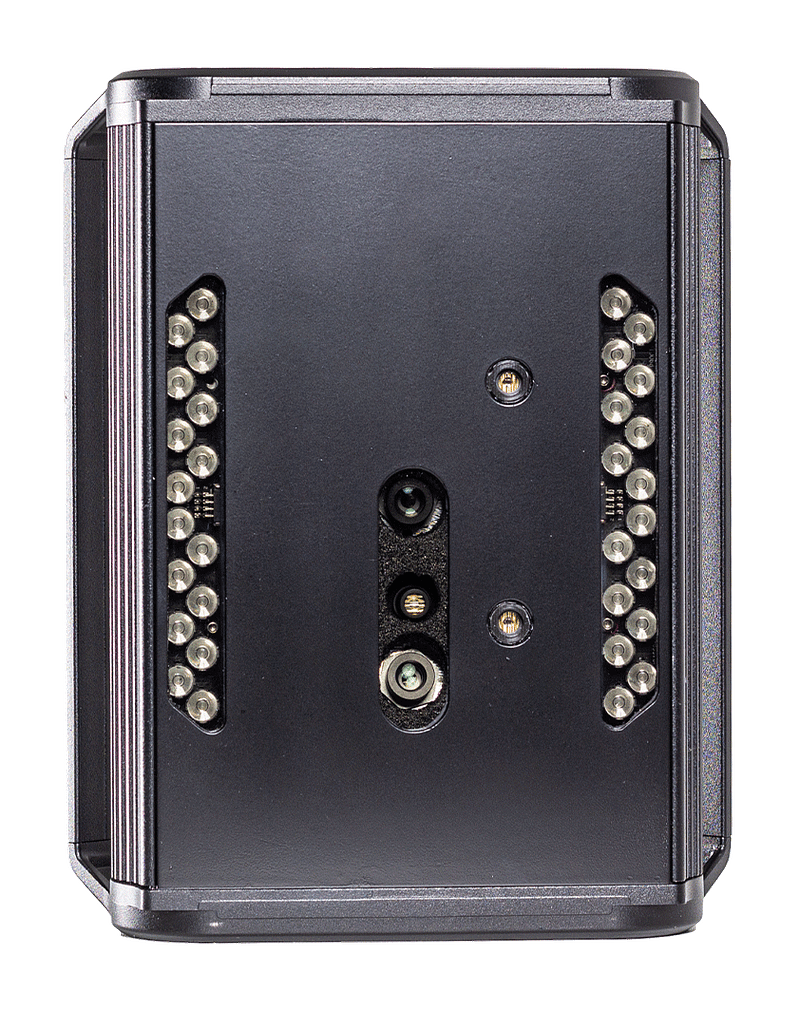

U70, Uniaxial extensometer

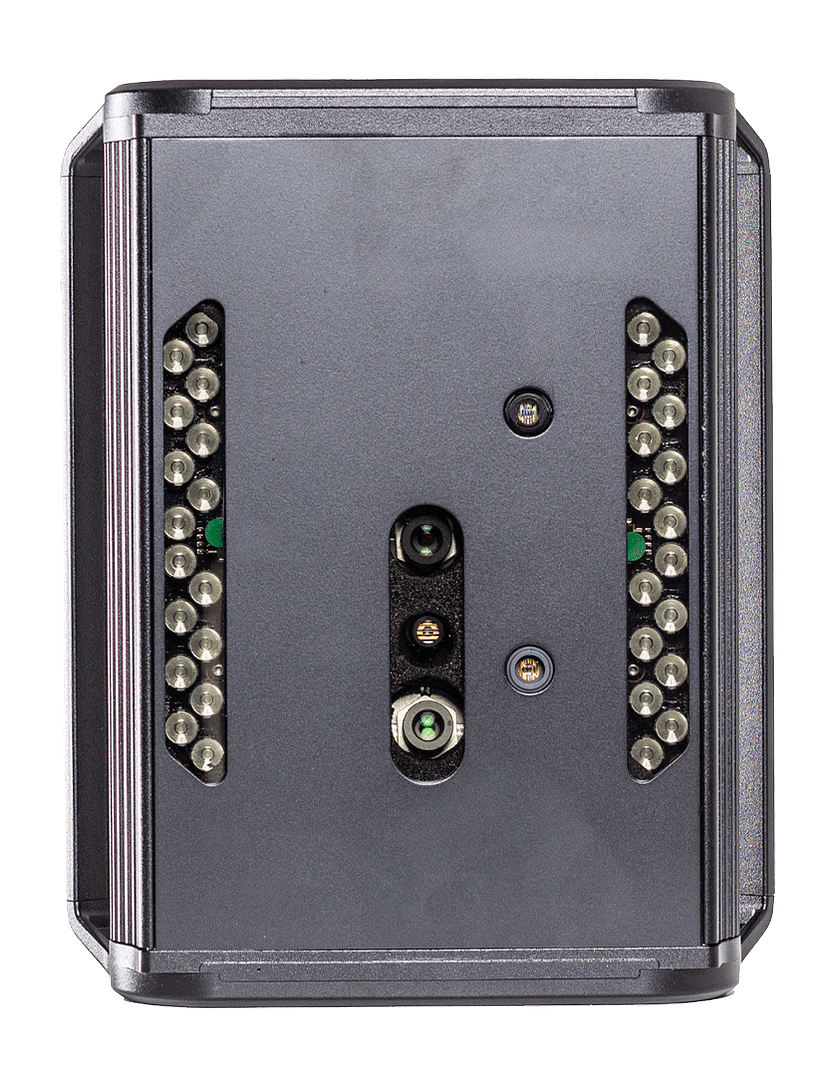

B80, Biaxial extensometer

Accurate

Vector’s real-time accuracy extends across a broad range of gauge lengths and elongations.

From common metals to polymers, Vector adapts to your needs, offering unparalleled accuracy meeting or exceeding ISO 9513 Class 0.5 and ASTM E83 Class B-1 standards.

Install; Mark; Align; and Measure

With an intuitive four-step setup, Vector is operational in 40 seconds and ready to test the next specimen in just 2 seconds, boasting user-friendly features like alignment guidance and adaptive control via our Vector Interface app.

Versatile

The non-contact approach allows operators to use the same extensometer for a wide variety of different specimens and test types. Without the need to touch or alter the specimen, the extensometer does not influence the measurement, which is particularly important with delicate materials.

Low Cost of Ownership

The Vector range represents a significantly reduced capital investment compared to advanced extensometers such as video and automated systems, whilst also offering a comparable lifetime cost to that of a single clip-on extensometer system.

Products

Vector range

Vector U200

Vector

Uniaxial Extensometer

Gauge length: 25 to 180 mm

Minimum specimen width: 5 mm

Operating distance: 250 to 350 mm

Vector U70

Vector

Uniaxial Extensometer

Gauge length: 10 to 50 mm

Minimum specimen width: 2 mm

Operating distance: 280 to 320 mm

Vector B80

Vector

Biaxial Extensometer

Gauge length: Axial 7.5 to 70 mm Transverse 6 to 25 mm

Minimal specimen width: Axial 1.5 mm flat 2 mm round Transverse 10 mm flat 12.5 mm round

Operating distance: 285 to 315 mm

Frequently asked questions

Have a question?

Below you will find the answers to our most frequently asked questions in relation to our Vector Extensometer. For any additional questions, please fill out the contact form below.

How do I identify Vector dashboard icons?

Answer:

We have designed a comprehensive troubleshooting guide to help you resolve problems quickly and easily. You can find instructions and helpful tips in our Vector manual: Manual

What are the advantages of Vector over traditional extensometers?

Answer:

The term non-contact refers to the way Vector measures, requiring no physical contact with the test specimen. Therefore, no clip-ons, cables or sensors are placed on the specimen that requires testing.

The non-contact approach allows operators to use the same extensometer for a wide variety of different specimens and test types. Without the need to touch or alter the specimen, the extensometer does not influence the measurement, which is particularly important with delicate materials. This process is far more efficient, as it only requires simple specimen marking.

Vector builds on years of measurement experience and knowledge in the material testing and metrology fields, culminating in a precision measurement solution resilient to the many challenges of laboratory testing.

How easy is Vector to use?

ANSWER:

Vector is up and running with four easy steps: Install; Mark; Align; and Measure, Vector can be operational in just 40 seconds.

To aid the operator, Vector is rich in user feedback, such as alignment guidance, status indication and adaptive guidance via the Vector Interface app.

What testing is Vector suitable for?

ANSWER:

Vector is suitable for most universal test machines and can be used in applications at ambient temperature and with temperature chambers, Vector outputs measurements in real-time via analogue +/-10V BNC connection.

Vector’s automatic and adaptive control reduces complexity for users and streamlines testing. Vector can be configured to work with different mark types, gauge lengths and outputs. It is well suited to both the common and unusual materials in the metal, composite and polymer industries.

Vector accommodates multiple gauge lengths within one extensometer, including outputting in both strain and extension. Vector is suitable for a range of specimen geometries, environmental conditions and UTMs. Using Vector removes the need to manage delicate contactable extensometers and can test to failure uninterrupted.

How does Vector automate measurements?

ANSWER:

Vector produces extensometry measurements automatically, which significantly reduces the operator handling, test time and likelihood of error. Each Vector has an optically calibrated region of measurement, defined by clear laser guides. Using specific pattern recognition for the marked specimen, Vector can output precision strain measurements repeatably in less than a second without the need for precise positioning or configuration.

What type of technology does Vector use?

ANSWER:

Vector is a closed-loop vision-based system, which benefits from AI processing to produce accurate measurements from a variety of standard specimen marking methods.

Through Artificial Intelligence, Vector captures, analyses and outputs measurement information to the user in a quick and automated method, with minimal operator interaction.

What is a biaxial extensometer?

ANSWER:

“Biaxial” means measuring in two perpendicular directions simultaneously, typically one in line with the load and the other transverse, across the width of the specimen.

What benefit does a biaxial extensometer provide over uniaxial?

ANSWER:

Measuring both transverse and axial strains allows further material information to be calculated from the way these strains behave. Biaxial extensometers are used to help calculate Poisson’s ratio; the Plastic Strain Ratio, r; and the Tensile Strain Hardening Exponent, n.

Can all Vector's measure in biaxial?

ANSWER:

The B in the name Vector B80 denotes that it is a biaxial extensometer. U70 and U200 are uniaxial only. The B80 can also measure uniaxially, when configured, and is suited for specimens smaller than those suitable for the U70.

What biaxial measurements can Vector perform?

ANSWER:

A biaxial Vector requires similar markings to other Vectors – either a speckle pattern or an arrangement of rings for both axial and transverse gauges. Vector outputs a single transverse measurement from these markings.

How should I maintain and clean my Vector?

ANSWER:

To maintain the optimal performance of your Vector extensometer, it’s crucial to keep the front face free from dust, grease and other contaminants. Here’s how to properly care for it:

- Cleaning: Use a clean microfiber cloth to gently wipe the centre window. The window is made from optical-grade cast acrylic, which is prone to scratching, so avoid using abrasive materials.

- Removing debris: For any debris buildup, use low-pressure compressed air (like an air duster) to blow it off. Ensure the nozzle is at least 150mm away from the front face to avoid damage.

- Handling marks or smudges: If you notice any marks or smudges, they should be gently wiped away with a microfiber cloth.

contact

Book a Demo

For a technical demo and more information on how Vector can meet your measurement needs, please fill out the form below.